Preventive Maintenance Checklist PDF: An Overview (12/17/2025)

Today, December 17, 2025, marks a pivotal moment for streamlined asset upkeep. PDF checklists are becoming essential for effective preventive maintenance programs, offering a standardized and easily distributable format for detailed inspections.

These digital forms ensure consistent data collection, improving reliability and reducing unexpected downtime. Implementing a robust checklist system, often integrated with CMMS, is crucial for long-term success.

Preventive maintenance (PM) is a proactive approach to asset care, shifting from reactive repairs to scheduled upkeep. Utilizing a preventive maintenance checklist PDF is central to this strategy, providing a structured method for regular inspections and tasks. This approach minimizes unexpected breakdowns, extends equipment lifespan, and reduces overall maintenance costs.

A well-defined checklist ensures all critical components are examined, and necessary actions – like oil changes or filter replacements – are completed on time. The Australian Government’s focus on preventive health parallels this concept, emphasizing proactive measures for long-term wellbeing. Similarly, PM safeguards assets, promoting operational efficiency and reliability. PDF format facilitates easy distribution and record-keeping, vital for compliance and continuous improvement.

The Importance of a Preventive Maintenance Checklist

A preventive maintenance checklist PDF is paramount for operational efficiency and safety. Without a structured checklist, crucial maintenance steps can be overlooked, leading to equipment failure and costly downtime. Like Australia’s National Preventive Health Strategy aiming to reduce preventable health conditions, a PM checklist proactively addresses potential issues before they escalate.

PDF format ensures standardized procedures across teams, improving consistency and accountability. Detailed checklists facilitate accurate record-keeping, supporting data analysis for optimization. Investing in preventive measures, mirroring the government’s commitment to preventive health, ultimately reduces long-term expenses and enhances asset reliability. A clear checklist is the foundation of a successful PM program.

Creating an Effective Preventive Maintenance Checklist

Developing a robust preventive maintenance checklist PDF requires careful planning. Identify assets, determine frequencies, and list tasks— mirroring Australia’s strategy for preventative health initiatives.

Identify Your Assets

The foundational step in crafting a preventive maintenance checklist PDF is a comprehensive asset inventory. Meticulously document every piece of equipment requiring upkeep – mirroring the detailed reporting needed for Australian preventive health programs like colonoscopy adverse event forms.

Include details like manufacturer, model number, serial number, location, and installation date. Categorize assets by type (e.g., HVAC, electrical, vehicles) for streamlined checklist creation. This detailed asset list ensures no critical equipment is overlooked during scheduled maintenance. Accurate identification is paramount, similar to the focus on identifying health conditions preventable through proactive measures, as highlighted by Australian government initiatives.

A well-defined asset list forms the backbone of an effective preventive maintenance strategy.

Determine Maintenance Frequency

Establishing appropriate maintenance intervals is vital when building a preventive maintenance checklist PDF. Frequency should align with manufacturer recommendations, operational demands, and historical failure data – mirroring the long-term planning of Australia’s National Preventive Health Strategy.

Consider factors like usage intensity, environmental conditions, and criticality of the asset. Some tasks may require daily checks, while others are suitable for weekly, monthly, or annual schedules. Regular reviews, akin to the ongoing assessment of public health research initiatives, are essential to optimize these intervals.

A balanced approach prevents both premature maintenance and catastrophic failures, ensuring cost-effectiveness and reliability.

List Maintenance Tasks

A comprehensive preventive maintenance checklist PDF demands a detailed listing of all necessary tasks. These should encompass inspections, lubrication, adjustments, cleaning, and component replacements – mirroring the thoroughness of Australia’s focus on preventive health initiatives.

Tasks must be specific and actionable, avoiding ambiguity. For example, instead of “Inspect motor,” specify “Check motor for unusual noises, vibrations, and overheating.” Prioritize tasks based on criticality and potential impact on operations.

Regularly update this list based on performance data and evolving best practices, similar to the ongoing refinement of the National Preventive Health Strategy.

Key Components of a Preventive Maintenance Checklist PDF

Essential elements include asset details, task descriptions, frequency schedules, and record-keeping sections. These components, mirroring Australia’s health strategies, ensure thoroughness and accountability.

Essential Checklist Sections

A comprehensive preventive maintenance checklist PDF requires several key sections for optimal functionality. Firstly, a dedicated area for asset information is vital, detailing equipment name, ID, location, and manufacturer specifics. Next, maintenance task descriptions should clearly outline each step, ensuring technicians understand the procedure.

Crucially, a frequency and scheduling section dictates when tasks are due, aligning with the overall maintenance plan. Furthermore, robust record-keeping and sign-off areas are essential for documenting completed work, noting any issues, and verifying completion by a qualified technician. These sections, mirroring the structured approach of national health strategies, promote accountability and data-driven decision-making.

Asset Information Details

The asset information section within a preventive maintenance checklist PDF is paramount for accurate tracking and efficient workflow. This section should meticulously detail the equipment name or identifier, ensuring clear recognition. Including the manufacturer’s details, such as model and serial number, aids in sourcing parts and accessing specific documentation.

Furthermore, noting the asset’s location within the facility streamlines technician dispatch and minimizes search time. Adding the date of purchase and installation provides valuable insight into the asset’s lifecycle. Similar to health record keeping, detailed asset data supports informed maintenance decisions and extends equipment lifespan, mirroring Australia’s focus on preventative measures.

Maintenance Task Descriptions

Within a preventive maintenance checklist PDF, detailed task descriptions are crucial for clarity and consistency. Each task should be outlined with step-by-step instructions, leaving no room for ambiguity. Specify the required tools and materials needed for each procedure, ensuring technicians are fully prepared.

Clearly define safety precautions associated with each task, prioritizing technician well-being. Include acceptable performance criteria – what constitutes a successful completion of the task. Like Australia’s national health strategy emphasizing preventative actions, these descriptions proactively address potential issues. Well-defined tasks minimize errors and contribute to a more reliable and efficient maintenance program.

Frequency and Scheduling

A preventive maintenance checklist PDF must clearly define task frequencies – daily, weekly, monthly, quarterly, or annually. Scheduling is paramount; integrate checklists with a calendar system or CMMS for automated reminders, mirroring the long-term planning of Australia’s National Preventive Health Strategy.

Consider runtime hours or usage cycles for equipment-specific intervals. Prioritize critical assets with more frequent checks. The PDF should indicate due dates and responsible personnel for each task. Regular reviews, like those in health initiatives, ensure schedules remain effective. Proper scheduling minimizes downtime and extends asset lifespan, optimizing resource allocation.

Record Keeping and Sign-Off

A comprehensive preventive maintenance checklist PDF necessitates robust record-keeping features. Each completed checklist should store data – date, technician, observations, and actions taken – mirroring the detailed reporting in health programs. Digital signatures provide accountability and verification, similar to adverse event reporting forms.

The PDF should facilitate easy data retrieval for trend analysis and performance evaluation. Maintain a centralized repository for all completed checklists, ensuring accessibility for audits and future reference. This detailed documentation supports informed decision-making and continuous improvement, vital for long-term asset health and reliability.

Types of Preventive Maintenance Checklists

PDF checklists vary by application: general equipment, vehicle maintenance, HVAC systems, and electrical systems each require tailored inspection points for optimal performance and safety.

General Equipment Checklist

A comprehensive general equipment checklist, often formatted as a PDF, is foundational for any preventative maintenance program. These checklists typically encompass visual inspections for wear and tear, lubrication of moving parts, and verification of safety features like guards and emergency stops.

Regularly scheduled checks, documented within the PDF, should include tightening loose bolts, cleaning debris, and assessing the condition of hoses and cables. Detailed task descriptions within the PDF ensure consistency among technicians.

Furthermore, the checklist should prompt recording of serial numbers, maintenance dates, and technician signatures for audit trails. Utilizing a PDF format allows for easy distribution, digital signatures, and centralized storage of maintenance records, improving overall equipment reliability and lifespan.

Vehicle Maintenance Checklist

A vehicle maintenance checklist, ideally in PDF format, is critical for ensuring fleet safety and minimizing operational costs. These checklists should include routine inspections of fluid levels – oil, coolant, brake fluid, and windshield washer fluid – alongside tire pressure and tread depth assessments.

Brake system checks, light functionality verification, and a review of belts and hoses are also essential components. The PDF should prompt documentation of mileage at each service interval, along with any observed issues or repairs needed.

Digital checklists facilitate easy record-keeping, allowing for proactive scheduling of maintenance and tracking of vehicle performance. Consistent use of a standardized PDF checklist improves vehicle longevity and reduces the risk of breakdowns.

HVAC System Checklist

An HVAC system checklist, best utilized as a PDF, is vital for maintaining indoor air quality and energy efficiency. These checklists should detail regular filter replacements, crucial for optimal airflow and system performance. Inspecting and cleaning coils, checking refrigerant levels, and verifying proper ventilation are also key components.

The PDF format allows for standardized documentation of these tasks, including dates, technician initials, and any identified issues. Checking for leaks, assessing ductwork integrity, and calibrating thermostats contribute to system longevity.

Digital checklists streamline record-keeping, enabling proactive maintenance scheduling and reducing costly emergency repairs. Consistent use ensures a comfortable and healthy environment.

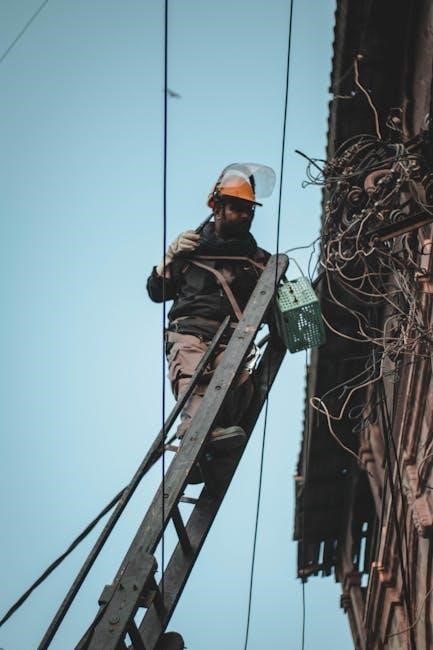

Electrical System Checklist

A comprehensive electrical system checklist, ideally in PDF format, is paramount for safety and operational reliability. Regular inspections should include visual checks for damaged wiring, loose connections, and overloaded circuits. Testing of circuit breakers and ground fault circuit interrupters (GFCIs) is essential for preventing electrical hazards.

PDF checklists facilitate detailed documentation of these inspections, including test results and any corrective actions taken. Checking for proper grounding, verifying panelboard cleanliness, and inspecting transformers are also vital components.

Digital checklists improve record-keeping, enabling proactive maintenance and minimizing the risk of electrical failures and fires.

Utilizing PDF Format for Checklists

PDF checklists offer portability, security, and ease of distribution for maintenance teams. They ensure consistent formatting and reliable record-keeping, streamlining the entire process.

Benefits of PDF Checklists

PDF format provides numerous advantages for preventive maintenance checklists. Firstly, PDFs are universally accessible, viewable on virtually any device without requiring specialized software, ensuring broad usability across teams. Secondly, they maintain consistent formatting, preventing alterations during distribution and guaranteeing standardized data collection.

Furthermore, PDFs enhance security by allowing password protection and restricted editing, safeguarding sensitive maintenance records. They also facilitate easy archiving and retrieval of historical data, crucial for trend analysis and continuous improvement. Digital PDF checklists reduce paper consumption, promoting environmental sustainability and lowering administrative costs.

Finally, PDFs support digital signatures for task sign-off, providing a clear audit trail and accountability. This combination of accessibility, consistency, security, and efficiency makes PDF checklists an ideal solution for modern maintenance management.

PDF Editing and Customization

While PDFs offer format consistency, many tools allow for editing and customization to suit specific needs. Software solutions enable adding company logos, adjusting field types (checkboxes, dropdowns, text fields), and incorporating digital signatures directly into the checklist template.

Customization extends to tailoring checklists for different asset types and maintenance procedures, ensuring relevance and accuracy. Advanced features include conditional formatting, where sections appear based on previous responses, streamlining the inspection process.

Furthermore, some platforms offer collaborative editing, allowing multiple users to contribute to checklist design and updates. This flexibility ensures that PDF checklists remain dynamic tools, adapting to evolving maintenance requirements and organizational standards, maximizing their effectiveness.

Digital vs. Paper Checklists

The shift from paper-based to digital preventive maintenance checklists offers significant advantages. Digital checklists, often in PDF format, facilitate easier data collection, storage, and analysis, eliminating the risk of lost or damaged forms.

Real-time data synchronization allows for immediate identification of maintenance needs and improved communication between teams. Paper checklists, while simple, are prone to errors, difficult to track, and require manual data entry, increasing administrative overhead.

Digital solutions also enable automated scheduling, reminders, and reporting, enhancing efficiency and compliance. Ultimately, embracing digital checklists streamlines the entire maintenance process, leading to reduced downtime and increased asset lifespan.

Resources for Preventive Health & Maintenance

The Australian Government invests in preventive health, allocating $1.9 million and aiming for 5% of health expenditure by 2030. Research initiatives, like the $545.1 million fund, support innovative approaches to wellbeing.

Australian Government Initiatives

The Australian Government demonstrates a strong commitment to preventative health through substantial investments and strategic initiatives. A $1.9 million investment is underway to bolster the preventative health system, supporting the National Preventive Health Strategy launched in 2023. This ten-year plan aims to enhance the health and wellbeing of all Australians across their lifespans.

Furthermore, the Preventive and Public Health Research Initiative will provide $545.1 million over ten years, beginning in 2024-25. This funding will fuel targeted research into novel methods for addressing health risks and promoting healthier environments. The government envisions preventative health reaching 5% of total health expenditure by 2030, signifying a paradigm shift towards proactive healthcare.

National Preventive Health Strategy

The National Preventive Health Strategy, a ten-year plan initiated in 2023, represents a cornerstone of Australia’s proactive healthcare approach. It focuses on fostering supportive and healthier environments, aiming to prevent nearly half of all Australian health conditions currently deemed preventable. This strategy builds upon previous successes and seeks to establish a sustainable prevention system for the future.

The strategy’s initial focus is on addressing key risk factors and promoting wellbeing across all life stages. It underscores the importance of early intervention and preventative measures, aligning with the benefits of a well-executed preventive maintenance checklist – proactively addressing issues before they escalate into larger, more costly problems.

Preventive and Public Health Research Initiative

Launched in 2024, the Preventive and Public Health Research Initiative represents a substantial investment of $545.1 million over ten years. This initiative is dedicated to funding targeted research aimed at discovering innovative approaches to address critical health risks and enhance public wellbeing. The focus is on identifying new strategies for prevention and early intervention.

Similar to the detailed analysis enabled by data collected from a comprehensive preventive maintenance checklist PDF, this research initiative seeks to leverage data and insights to optimize preventative measures. It aims to move beyond reactive solutions towards proactive, evidence-based strategies for improved health outcomes and resource allocation.

Checklist Examples & Templates

Basic items include oil changes and filter replacements, while advanced features integrate digital sign-off and detailed asset information within the PDF checklist format.

Basic Maintenance Checklist Items

Fundamental preventive maintenance checklists, often formatted as PDFs, typically include core tasks applicable across various equipment types. These commonly feature regular inspections for wear and tear, lubrication of moving parts, and fluid level checks – encompassing oil, coolant, and hydraulic fluids.

Filter replacements (air, oil, fuel) are standard, alongside belt and hose inspections for cracks or damage. Tightness checks of bolts and connections are vital, as is verifying proper operation of safety devices. Basic electrical checks, like inspecting wiring for fraying, also feature prominently.

These foundational items, documented within the PDF, contribute significantly to extending equipment lifespan and minimizing unexpected failures, forming the bedrock of a proactive maintenance strategy.

Advanced Checklist Features

Beyond basic items, advanced preventive maintenance checklist PDFs incorporate features for enhanced efficiency and data analysis. These include digital signature capture for accountability, timestamping for tracking completion, and integration with QR codes linking to equipment manuals or repair histories.

Conditional logic allows checklists to adapt based on previous responses, triggering specific tasks only when needed; Photo documentation capabilities enable visual record-keeping of equipment condition. Some PDFs support automated scheduling and notifications, prompting technicians for upcoming maintenance.

Furthermore, data export functionality facilitates trend analysis and performance reporting, supporting predictive maintenance initiatives and optimizing maintenance schedules for maximum effectiveness.

Implementing and Managing Checklists

Successful checklist adoption requires thorough personnel training and regular reviews to ensure relevance. Integrating PDF checklists with a CMMS system streamlines workflow and data analysis.

Training Personnel

Effective implementation of a preventive maintenance checklist PDF system hinges on comprehensive personnel training. Technicians must understand how to accurately complete the checklist, including proper data entry and reporting procedures. Training should cover the specific assets, maintenance tasks, and safety protocols outlined within the PDF forms.

Furthermore, emphasize the importance of consistent checklist usage and the benefits of detailed record-keeping. Supervisors should also receive training on how to review completed checklists, identify trends, and address any recurring issues. A well-trained team ensures data integrity, maximizes the effectiveness of the maintenance program, and minimizes potential equipment failures. Regular refresher courses are also recommended to reinforce best practices.

Regular Checklist Reviews

Consistent review of completed preventive maintenance checklist PDFs is paramount for program optimization. These reviews should identify trends, recurring issues, and potential areas for improvement in maintenance procedures. Analyzing the data captured within the checklists allows for proactive adjustments to maintenance schedules and task lists.

Look for patterns indicating premature equipment failure or tasks consistently requiring extended completion times. This feedback loop informs updates to the checklist itself, ensuring it remains relevant and effective. Regular reviews also validate the accuracy of data entry and adherence to established protocols, bolstering the overall reliability of the maintenance program.

Integrating with CMMS Systems

Seamless integration of preventive maintenance checklist PDFs with a Computerized Maintenance Management System (CMMS) dramatically enhances efficiency. This connection automates data transfer from completed checklists directly into the CMMS database, eliminating manual entry and reducing errors.

CMMS integration facilitates comprehensive reporting, allowing for detailed analysis of maintenance costs, equipment performance, and technician productivity. Automated work order generation triggered by checklist findings streamlines the repair process. This synergy provides a centralized platform for managing all aspects of preventive maintenance, fostering proactive asset care and minimizing downtime.

Future Trends in Preventive Maintenance

Predictive maintenance, IoT sensors, and data analytics are revolutionizing checklists. PDF formats will evolve to dynamically integrate real-time data, optimizing maintenance schedules and improving asset reliability.

Predictive Maintenance Integration

The future of preventive maintenance checklists lies in seamless integration with predictive maintenance technologies. Traditional, time-based checklists are evolving into dynamic tools informed by real-time data from IoT sensors and advanced analytics.

PDF checklists can be designed to automatically update task lists based on asset condition, moving from reactive to proactive maintenance. This integration allows for condition-based maintenance, focusing efforts only when needed, reducing unnecessary interventions and costs.

Data analytics will identify patterns and predict potential failures, triggering specific checklist items and streamlining the maintenance process; This shift optimizes resource allocation and extends asset lifespan, ultimately enhancing overall operational efficiency.

IoT and Sensor-Based Monitoring

The integration of Internet of Things (IoT) devices and sensor-based monitoring is revolutionizing preventive maintenance checklists. These technologies provide continuous, real-time data on asset performance, moving beyond scheduled inspections to condition-based maintenance.

PDF checklists can be dynamically populated with sensor readings, automatically flagging potential issues and triggering specific maintenance tasks. This proactive approach minimizes downtime and optimizes resource allocation. Sensors monitor vibration, temperature, pressure, and other critical parameters, feeding data directly into the checklist system.

This data-driven approach enhances accuracy and efficiency, ensuring maintenance is performed only when necessary, extending asset life and reducing overall costs.

Data Analytics for Optimization

Leveraging data analytics with preventive maintenance checklist PDFs unlocks significant optimization opportunities. Collected data from completed checklists, combined with sensor readings, reveals patterns and trends previously hidden.

Advanced analytics can predict equipment failures, refine maintenance schedules, and identify areas for process improvement. This allows for a shift from reactive to proactive maintenance strategies, minimizing downtime and maximizing asset lifespan. Analyzing checklist completion rates and task durations highlights inefficiencies.

Data-driven insights enable organizations to prioritize maintenance efforts, optimize resource allocation, and continuously improve the effectiveness of their preventive maintenance programs.